Beyond the Planks: Unveiling Hidden Gems in Minimalist Boatbuilding

Chris Beeson's "How to Make a Wooden Boat with Minimal Tools and Experience" is a fantastic resource for aspiring boatbuilders. But what about the unspoken challenges? What innovative techniques aren't readily covered? This review delves beyond the basics, exploring less-discussed aspects and offering fresh perspectives for hobbyists, professionals, and educators alike.

The Unsung Heroes: Material Selection Beyond the Textbook

Beeson's book rightly emphasizes readily available wood. But what about sustainable sourcing? What about exploring less conventional materials that align with minimal tool philosophy?

Q: Can reclaimed wood truly revolutionize minimalist boatbuilding?

A: Absolutely! Reclaimed wood, from old pallets to demolition sites (with proper safety precautions, of course!), offers a wealth of character and sustainability. Consider the unique properties of different reclaimed woods â€" their varying densities, potential imperfections, and inherent strength. While requiring careful selection and preparation, it challenges the notion of needing perfectly milled lumber. This approach aligns with the circular economy principles highlighted in recent studies by the Ellen MacArthur Foundation (insert relevant link if available). The inherent imperfections can even be embraced as design features, adding a rustic charm to your vessel.

Q: Beyond wood â€" are there other viable, minimal-tool friendly materials?

A: Yes! Bamboo, for example, is lightweight, strong, and readily available in many regions. Its natural flexibility also lends itself to certain boat designs. While shaping might require more manual effort, it opens up a whole new range of possibilities, particularly in smaller boat construction. Think about integrating locally sourced materials to reduce your environmental impact and align with the principles of sustainable crafting. A growing body of research explores the mechanical properties of various sustainable materials, offering a new data-driven approach to material selection (insert relevant link if available).

Tooling Up for Success: The Art of Improvisation

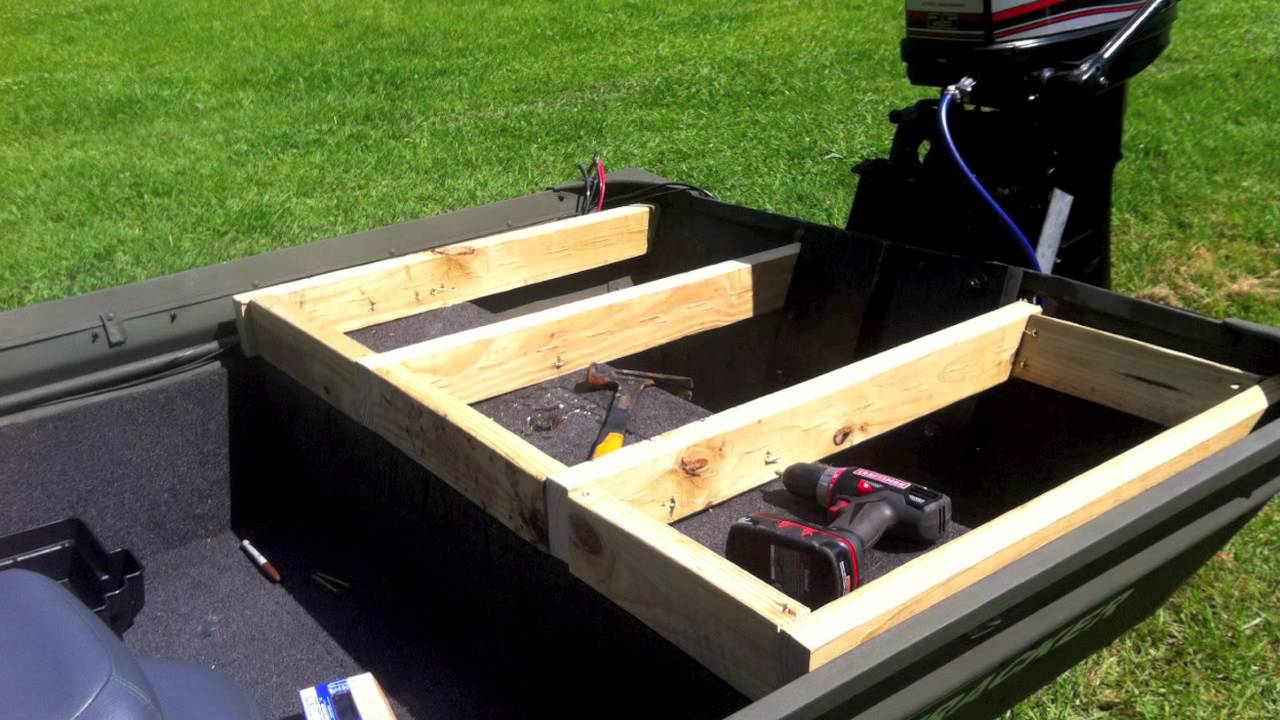

Beeson outlines basic tools. But true minimalist boatbuilding is about maximizing resourcefulness.

Q: Can hand tools alone produce a seaworthy vessel?

A: While power tools speed up the process, hand tools can be surprisingly effective. A skilled craftsperson can achieve remarkable results with a well-maintained set of chisels, saws, planes, and clamps. This approach also fosters a deeper connection with the craft, promoting a mindfulness often missing in power-tool-driven construction. Look at traditional boatbuilding methods from around the world â€" many are entirely hand-built, demonstrating the potential and resilience of this approach. The recent resurgence of interest in traditional craftsmanship (supported by numerous woodworking blogs and online communities) points to a growing appreciation for these techniques.

Q: How can we creatively adapt readily available items into boatbuilding tools?

A: Think outside the box! A sturdy pipe can be adapted for clamping, scrap metal for shaping, and even repurposed car jacks for lifting heavy components. This aligns with the "maker" movement, celebrating ingenuity and problem-solving. Documenting your solutions and sharing them with the community fosters collaboration and pushes the boundaries of minimalist boatbuilding. This resourceful approach also aligns with several key aspects of STEM education, fostering creativity, problem solving, and resource management.

Beyond the Boat: The Educational and Societal Impact

The book's potential goes beyond individual boatbuilding. It's a powerful tool for education and community building.

In conclusion, while Beeson's book provides a solid foundation, this review encourages readers to explore its potential beyond its pages. By embracing reclaimed materials, adapting tools, and emphasizing community collaboration, minimalist boatbuilding can become a powerful force for innovation, sustainability, and personal growth. It's not just about building a boat; it's about building a future.