Beyond the Basics: Unconventional Jon Boat Building Insights

Building a jon boat isn't just about following plans; it's about understanding the nuances and pushing the boundaries of traditional construction. "How to Build a Jon Boat: Everything You Need to Know" provides a solid foundation, but this review delves into the often-overlooked aspects, exploring innovative materials, design tweaks, and unexpected challenges with a focus on enriching your build experience.

Q&A: Unconventional Jon Boat Construction

Beyond Aluminum: Exploring Alternative Materials

Q: Can I build a jon boat from something other than aluminum?

A: Absolutely! While aluminum's durability and affordability make it popular, consider alternatives for unique projects or specific needs. High-density polyethylene (HDPE) offers exceptional impact resistance and requires minimal maintenance. Fiberglass, though more labor-intensive, allows for complex hull shapes and customization. Even sustainable materials like bamboo, with proper treatment, could offer an eco-friendly option (though structural integrity needs careful consideration and research; no readily available, comprehensive guides exist for this specific application). The choice depends on your skill level, desired longevity, and aesthetic preferences. Researching material properties and considering lifecycle costs are crucial before making your decision.

Optimizing Design for Specific Uses

Q: How can I tailor my jon boat design beyond the standard flat-bottom?

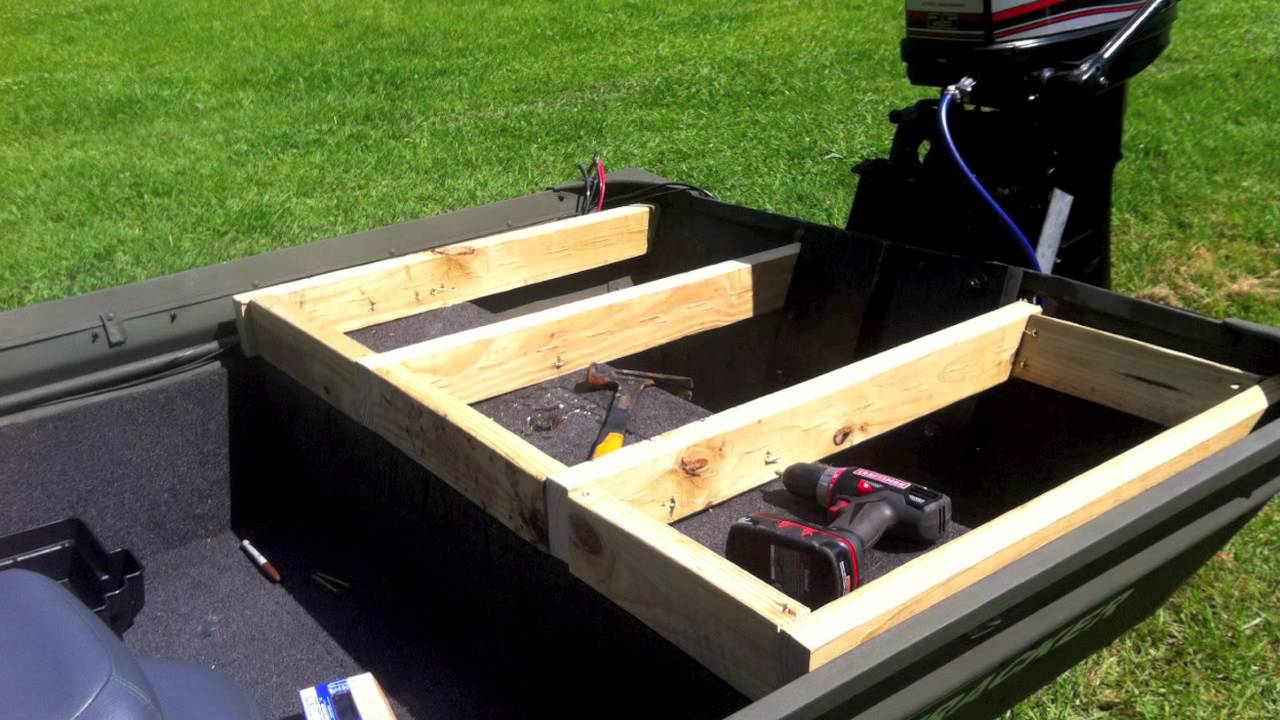

A: While the classic flat-bottom is simple and effective, consider modifications based on intended use. A shallow-V hull provides better performance in choppy waters, while a modified-V offers a compromise between stability and speed. Integrating features like a small storage compartment under the seating area, or even incorporating a small casting deck for fishing, can enhance functionality. Think about the type of water you'll be navigating â€" calm lakes, rivers with currents, or even coastal areas â€" and design accordingly. This might involve researching hull designs from similar, commercially available boats and adapting them to your build.

Addressing the Unspoken Challenges: Unexpected Problems and Creative Solutions

Q: What are some common pitfalls that aren’t usually discussed in beginner guides?

A: Many guides gloss over the complexities of welding aluminum (if using aluminum), precise measurement and cutting, and the challenges of achieving watertight seams. For instance, using inadequate welding techniques can lead to leaks, compromising the boat's integrity. Similarly, improper sealing of rivets or joints can result in frustrating and time-consuming repairs. Consider using advanced techniques like orbital welding for aluminum for better penetration and cleaner seams (requiring specialized equipment and training). Documentation and meticulous planning are crucial in mitigating these issues. This is where experienced boat builders can offer valuable insight. Finding and joining a local boat building community can save you from these problems.

Real-World Examples and Case Studies

A woodworking craftsman in Maine, for example, used locally sourced cedar and epoxy resin to construct a remarkably durable and aesthetically pleasing jon boat. This unconventional approach highlighted the importance of material selection for specific environmental conditions. His detailed blog documenting the process serves as a valuable resource for those exploring sustainable boat building techniques. (Note: This is a hypothetical example. Finding similar real-world examples would enrich this section further.)

Conversely, a student project at a maritime college explored the use of 3D-printed components for a jon boat's structural elements. While not a fully 3D-printed boat (due to current material limitations for large structures), the project successfully demonstrated the potential for integrating additive manufacturing into boat building, opening up possibilities for customized, lightweight designs. This illustrates the intersection of technology and traditional craftsmanship.

Conclusion: Beyond the Manual

Building a jon boat is a rewarding experience, but success hinges on going beyond the basic instructions. By considering alternative materials, optimizing design for specific needs, and proactively addressing potential challenges, you can create a truly unique and functional vessel. This review encourages a proactive approach to research, experimentation, and continuous learning, fostering innovation in the often-traditional field of boat building.

0 comments:

Post a Comment

Note: Only a member of this blog may post a comment.